More Fastener Manufacturers

Industrial fasteners are critical hardware components used to join materials and ensure mechanical stability in a vast range of assemblies. This extensive category encompasses over 500,000 types of hardware fasteners, serving myriad applications in both industrial and commercial environments. Fasteners are essential in diverse sectors, including automotive manufacturing, construction, furniture production, household appliances, military and defense, HVAC systems, surgical and medical devices, aerospace engineering, electronics, and security systems, where they play vital roles in assembly, structural integrity, and operational safety.

Industrial fasteners encompass a broad range of fastening tools and joining mechanisms used to connect parts, either permanently or temporarily. Common types include bolts, nuts, screws, flanges, rivets, and hinges. In sectors like automotive manufacturing, aerospace engineering, oil and gas extraction, and chemical processing, adherence to fastener standards is crucial for reliability and safety. Ensuring quality in fastener selection and installation is paramount to mitigate failure risks and uphold product integrity.

History of Fasteners

The history of fasteners is ancient, with the screw fastener likely invented by the ancient Egyptians for early woodwork and press technology. The Greeks significantly advanced fastener mechanics, with Archytas of Tarentum creating the first screw threads around 400 BC. Later, Archimedes developed the screw principle and designed wooden water screws for removing bilge water from ships and irrigating farms. Screws were also used for mechanical pressing, such as pressing grapes and olives for juice and oil. Much of this knowledge comes from artifacts, like those found in Pompeii, where screws were used in medical instruments. The first written mention of the screw appeared in the 1st century AD in Heron of Alexandria’s “Mechanica.”

In the centuries following, European adoption of metal fasteners was catalyzed by Johann Gutenberg’s incorporation of them into his renowned printing press. This innovation spurred their gradual integration by artisans, notably in 15th century applications such as armor assembly and clock making. Leonardo da Vinci further advanced the concept with designs for screw-cutting machines, later realized by Jacques Besson in 1560. Besson’s success led to the development of screw cutting plates, enhancing the adaptability of existing lathes. By the 1700s, advancements in engineering and manufacturing enabled semi-automation, exemplified by Antoine Thiout’s integration of a screw drive into lathes around 1750.

In the evolution of the industrial fastener industry, standards organizations have played a pivotal role. In the 1870s, the establishment of the US Standard Thread by visionary individuals marked a significant milestone. This initiative was followed by the formation of the Society of Automotive Engineers (SAE), which remains a leading authority in issuing fastener standards today. These early organizations took the initiative to establish consistent design recommendations and stringent quality standards, greatly simplifying consumer access to compatible equipment.

Throughout the 20th century, manufacturers propelled the industry forward with numerous innovative designs, such as the revolutionary self-drilling screw introduced in the 1960s. This era also witnessed a remarkable expansion in material diversity, exemplified by the adoption of nickel-based alloy fasteners in recent decades. These alloys offer superior heat resistance compared to traditional steel, reflecting ongoing advancements in material science and engineering.

Today, fastener manufacturers benefit from unprecedented technological capabilities, including state-of-the-art CNC machining, advanced quality control systems, and access to extensive raw material resources. This technological prowess has significantly diversified the fastener supply, meeting diverse industrial needs with precision and efficiency. Looking ahead, the industrial fastener industry is poised for continued innovation and growth, driven by relentless advancements in technology and expanding applications.

Fastener Design

Production Process

Fabricators produce threads on fasteners using various manufacturing methods. Initially, they mold, cast, or heat metal fasteners from sheet metal or bar stock. Threads are then formed through thread rolling or thread cutting. Thread rolling involves cold forming the metal under pressure to achieve the desired profile, enhancing abrasion resistance and thread strength. In thread cutting, manufacturers cut the thread pattern directly into the blank metal using precision lathes or CNC machines. Both methods are chosen based on the fastener’s intended application, volume, and required tolerances.

Materials

Fasteners are typically made of metal, though plastic is used in certain applications. Metal fasteners are commonly manufactured from materials such as steel, stainless steel, brass, bronze, and titanium. Steel, an iron alloy known for its formability, strength, and durability, is widely used across various applications depending on its carbon content. Stainless steel, an exceptionally durable alloy, is favored in industries like automotive engineering due to its strength and corrosion resistance. Brass, a copper and zinc alloy, is strong, corrosion-resistant, and aesthetically pleasing, making it suitable for decorative and functional items, especially those used in or near seawater. Bronze, another copper alloy combined with zinc, is ductile, lightweight, and a good conductor of heat and electricity, with a similar application range to brass despite its tendency to tarnish over time. Titanium, prized for its durability, light weight, and strength, is the top choice for the aerospace industry. In contrast, plastic fasteners are used in very light-duty applications, such as children’s toys, where strength is not a primary concern.

Are you evaluating which fastener material is best for your application? Steel fasteners are cost-effective and provide robust tensile strength, making them ideal for construction, automotive, and heavy machinery. Stainless steel fasteners offer superior corrosion resistance, perfect for marine, medical, and food processing environments. Brass fasteners add a decorative touch and resist tarnishing, suitable for electrical and plumbing installations. Titanium fasteners are lightweight and exceptionally strong, commonly used in aerospace, defense, and high-performance sports equipment. Plastic fasteners are non-conductive, corrosion-resistant, and lightweight, finding use in electronics, automotive interiors, and consumer goods.

Fastener Considerations and Customization

When designing or selecting fasteners for clients, manufacturers consider key variables such as load-bearing capacity, environmental conditions (such as exposure to chemicals, moisture, or temperature extremes), and space constraints.

These factors influence the customization of details like head type, length, material, coatings, screw grade strength, and decorative elements. Additionally, decisions on thread presence, texture (coarse or smooth), and measurements are made.

Each detail serves a specific purpose. A wider head distributes force over a larger surface area. Correct length ensures the fastener is flush with the surface. Protective coatings are applied for outdoor use to resist corrosion, UV damage, or chemical attack. In machinery, appropriate strength grades prevent breakage or failure under high loads or dynamic stresses. For decorative applications, manufacturers select fasteners that do not expose the head, such as countersunk or concealed head designs. Threads determine the functionality of the fastener, with different pitches and profiles suitable for specific materials and applications.

When should you consider custom fasteners? If your application has unique requirements—such as non-standard sizes, high-strength demands, or challenging environments—custom fasteners may offer the best fit and performance. Discuss your project specifications with experienced fastener manufacturers to explore available customization options, including materials, coatings, head designs, and special threading.

Types of Fasteners

For optimal organization, industrial fasteners can be categorized into two main groups: threaded and non-threaded fasteners. Threaded fasteners, like screws, bolts, and nuts, use helical ridges to secure components, providing reliable, often removable, connections. Non-threaded fasteners, such as rivets, pins, and clips, operate without threads to hold materials together, often creating permanent or semi-permanent bonds.

Threaded Fasteners

Threaded fasteners are characterized by spiral ridges, known as threads, on their bodies, which ensure secure attachment. Key types of threaded fasteners include nuts, bolts, screws, studs, clinching fasteners, hex bolts, self-tapping screws, cap screws, tap-end studs, double-end studs, and continuous-thread studs.

Nuts are metal blocks that work with bolts to create a strong connection between surfaces using internal threads that grip the bolt’s shaft. Bolts, featuring an external, partially threaded shaft, are paired with nuts to form nut and bolt assemblies. Users push bolts through workpieces and secure them with nuts on the other side.

Screws are externally threaded fasteners with a spiral thread and a head, allowing them to stay in place without additional hardware. Studs are metal rods with threads on both ends, ideal for high-strength applications and assemblies requiring frequent disassembly.

Clinching fasteners, also known as self-clinching or captive fasteners, deform ductile metal around a mounting hole, causing the displaced metal to flow into an annular recess in the fastener’s shank. This process contrasts with fasteners that deform upon installation and is widely used in electronics enclosures and thin sheet metal assemblies.

Hex bolts, with hexagonal heads, are commonly used in construction and heavy machinery, offering excellent torque and easy installation with standard wrenches. Self-tapping screws create their own holes as they are driven into materials such as wood, metal, and brick, although a pilot hole is necessary for metal.

Cap screws are fully threaded and used for fastening machine parts, providing high clamping force and precision alignment. Tap-end studs have long threads on one end and short threads on the other, with the long end known as the nut-end, which can be rounded or chamfered. Double-end studs have equal-length threads and chamfered points on both ends, typically used for flange bolting.

Continuous-thread studs are threaded from end to end without interruption and are also used for flange bolting, requiring two nuts for secure attachment.

Non-Threaded Fasteners

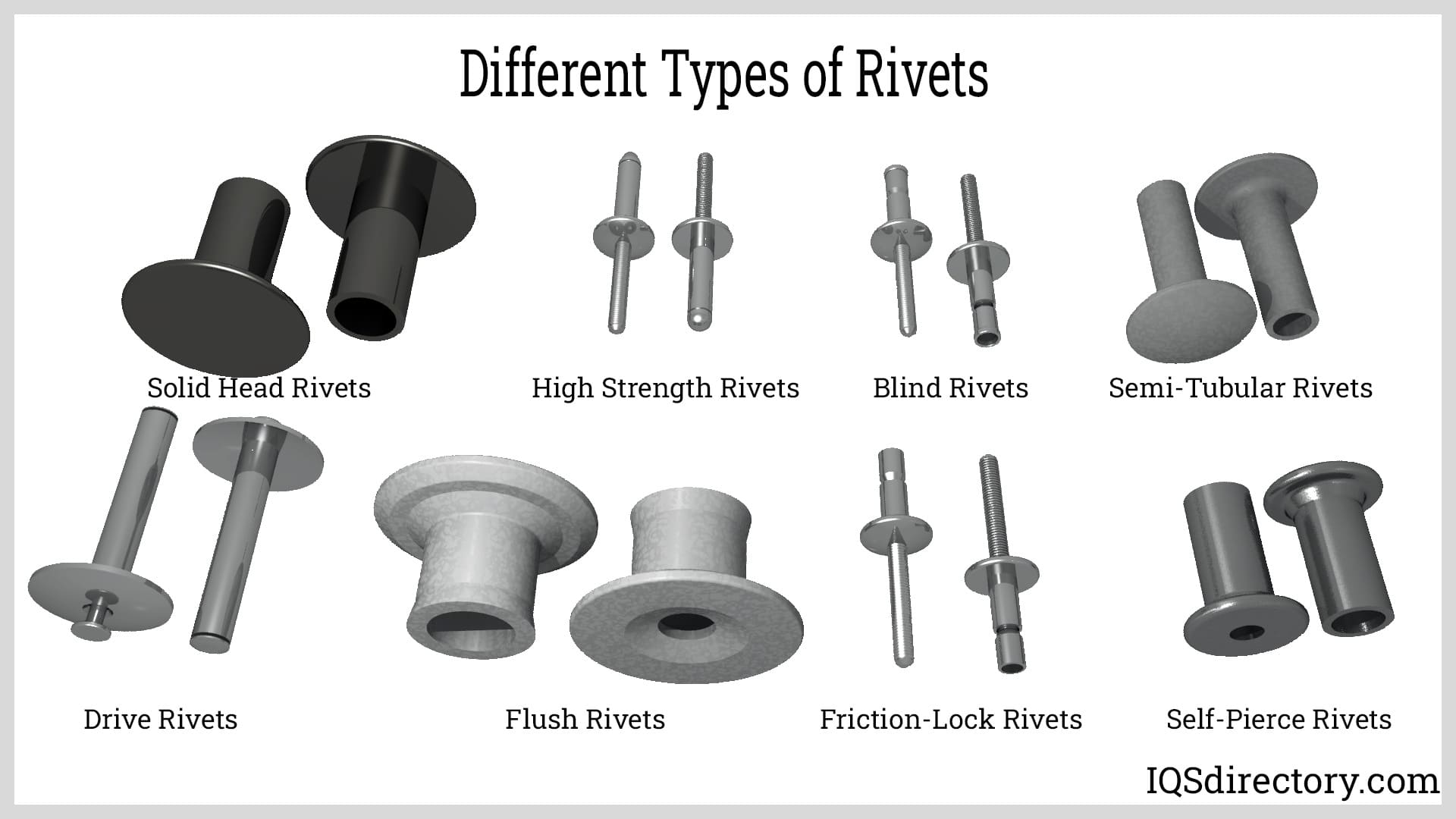

Non-threaded fasteners are those that lack threads, making them easier to install and remove without the need for tools like screwdrivers. Common types include pin fasteners, retaining rings, rivets, blind rivets, and dowel pins. Pin fasteners are typically cylindrical steel pins with a clip on the end, used to fasten or align machine parts. They are ideal for assemblies requiring frequent disassembly, such as tractor wagons, as they can be installed and removed quickly.

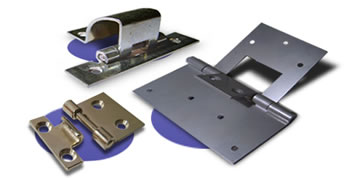

Retaining rings secure parts and assemblies in housings or onto shafts, preventing movement by locking into a groove. They are used in applications like pulleys, door hinges, electronics, and furniture. Rivets consist of a head and a smooth cylindrical shaft. They are installed by inserting them into a hole, causing the tail end to deform and expand, securing the rivet in place permanently. Rivets are commonly used alongside pins for durable, tamper-proof connections in pulleys and hinges.

Blind fastener rivets, also known as pop rivets or blind rivet nuts, are used to join two parts together at the rivet head. These fasteners consist of a tubular shaft with a mandrel running through the center. Installation involves inserting the rivet into a drilled hole and using a rivet gun to pull the mandrel. This action causes the mandrel to snap, expanding the rivet head and securing the parts. However, blind rivets are not recommended for critical structural applications due to the risk of the mandrel falling out and their susceptibility to vibration and corrosion. They are typically used in scenarios where only one side of the part is accessible.

Dowel pins, small solid cylindrical rods, ensure precise alignment by holding parts together. Commonly used in toy making and shelf supports, they can be rolled, tapered, or grooved to suit various applications.

Snap fasteners, also known as snaps, press studs, or poppers, are designed for clothing and bags. Made of two interlocking metal or plastic discs, they fasten with a simple press, often replacing buttons.

Need help choosing between threaded and non-threaded fasteners? Consider the strength, permanence, and ease of installation required for your application. Threaded fasteners are ideal for applications needing regular maintenance or adjustment, while non-threaded fasteners excel in permanent or high-speed assembly processes.

Self-drilling Screws

Self-drilling screws are versatile fasteners with a drill-shaped point, allowing them to penetrate materials without pre-drilled holes. Typically made of stainless steel, they enhance fastening efficiency and reduce installation time. Available in various sizes and lengths, their length is measured from the flat part of the head to the tip. For attaching wood to metal thicker than 1/2 inch, use fasteners with wings. The wings create a clearance hole, preventing premature thread engagement and ensuring the material remains securely attached to the base.

Stainless steel self-drilling screws are durable and long-lasting, ideal for various applications. The most common type of stainless steel for machine screws and nuts is 18-8 stainless steel (non-magnetic), suitable for drilling into soft materials like wood. For more demanding applications, particularly in metal, 410 stainless steel (magnetic) is used. This hardened type offers increased strength and stability. Self-drilling screws are preferred for rigorous applications and industries, providing advantages over self-tapping screws.

Threads

Threads are helical splines that spiral along the fastener’s shank. They come in various shapes and sizes, but two main types are commonly used. Machine screw threads are designed to pair with prepared threads in nuts or tapped holes, typically found on bolts, setscrews, and machine screws. Spaced threads are used in coach screws, self-tapping screws, woodscrews, and Type 25 thread cutters. These threads are usually designed to form their own threads in a pre-drilled hole and are ideal for use in wood, plastics, and softer metals.

Curious about thread types and compatibility? Explore machine screw threads for precision assemblies, or spaced threads for quick, secure fastening in woodworking and light-metal applications. Ensure the thread pitch and profile match your project’s material and strength requirements for optimal performance.

Fastener Accessories

Fastener accessories play crucial roles in optimizing fastening applications. Spacers, cylindrical or tubular components, create space between objects or fasteners, preventing metal-to-metal contact and ensuring alignment. Plugs seal holes left by fasteners, protecting surfaces from debris or fluids. Washers, thin discs with a central hole, distribute fastener loads, safeguard materials, and enhance the fastening process. Adhesive-backed dots, such as sticky circles and squares, provide an alternative for attaching lightweight objects in crafts and temporary mounting. Lastly, screw protectors, made of plastic or rubber, cover sharp edges to prevent accidental damage or injury.

The need for specific accessories is determined by the project’s requirements. Spacers are essential for precise component spacing, while plugs and washers are useful for sealing holes and protecting surfaces from contaminants. Sticky circles and squares are ideal for quick, temporary bonding, and screw protectors are necessary for exposed screws’ safety concerns. By evaluating the application and considering the desired outcomes, the required accessories can be identified.

Fastener accessories are widely accessible. Hardware stores and home improvement centers offer a broad selection of spacers, plugs, washers, sticky circles, and screw protectors, making them convenient for local purchases. Specialized fastener suppliers provide a more extensive range for specific needs. Online retailers also offer a vast array of options, allowing for easy browsing and purchasing from home or the workplace. Accessing these accessories is generally straightforward through both physical stores and online platforms, meeting specific project requirements.

Need guidance on which fastener accessories to use for your particular project or industry? Consult our comprehensive directory or reach out to fastener experts for tailored recommendations based on your use case.

Proper Fastener Care

To ensure the longevity of your metal and plastic fasteners, proper maintenance is essential. For metal fasteners, focus on preventing wear, corrosion, and rust, which are typically caused by impact, friction, and moisture. To mitigate impact and friction, either request a protective coating from your manufacturer or keep your fasteners well-lubricated. To prevent moisture damage, minimize exposure to moisture. For outdoor applications where moisture exposure is unavoidable, plastic fasteners are often a more suitable choice. Selecting the appropriate fastener for your application environment is crucial for optimal performance.

One common issue with stainless steel fasteners is galling, a form of wear caused by friction between two surfaces, often occurring during bolt installation through a threaded hole. Stainless steel is particularly susceptible to galling due to its adhesive properties. Most stainless steel fasteners have a coating that provides an additional protective layer between the thread materials.

Lubrication is the most effective and commonly used method to prevent galling in stainless steel, acting as a preventive layer that allows surfaces to slide easily without generating heat or friction. Utilizing two different steel grades, with varying hardness ratings, can also prevent galling by reducing the likelihood of mutual deformation. Additionally, reducing the installation speed minimizes friction between fastener materials. If resistance is felt during installation, it is advisable to stop immediately to prevent the galling from seizing completely. Avoid pulling the joints together, as this can deform the threads and damage the bolt.

Duplex stainless steel is renowned for its exceptional corrosion resistance, including high resistance to intergranular corrosion and stress corrosion cracking, even in chloride and sulfide environments. Its elevated chromium content provides robust protection against corrosion, though it can lead to embrittlement at around 300°C. Super duplex grades offer even greater corrosion resistance. Additionally, duplex stainless steel is twice as strong as austenitic stainless steel, allowing for cost savings through the use of thinner materials with higher allowable stress.

Duplex stainless steel is widely utilized across several industries, including chemical processing, transport, and storage, oil and gas exploration and offshore rigs, fabrication of oil and gas refining plants, marine equipment for seawater environments, pollution control equipment, pulp and paper manufacturing, and the fabrication of chemical process plants.

Hydrogen embrittlement, a condition where metals become brittle due to hydrogen absorption, affects hot-dip galvanized materials. The severity depends on the hydrogen acquired. To prevent this, minimize hydrogen exposure and bake materials at 190 to 220°C after electroplating to diffuse hydrogen. Using lower strength steels and reducing residual and applied stress can also mitigate cracking due to hydrogen embrittlement.

Looking for best practices to extend fastener lifespan? Regularly inspect fasteners for signs of corrosion, wear, or fatigue. Use the correct torque during installation, and always choose fasteners compatible with your application’s environmental conditions. For more tips, consult our fastener maintenance guide or speak to a fastener specialist.

Fastener Standards

When purchasing industrial fasteners, ensure they meet the specific requirements of your application, industry, and location. For military applications, fasteners must adhere to federal military specifications, known as “mil spec fasteners.” While the U.S. government provides various design standards, many industries also rely on standards from SAE, ASTM, or ISO.

Additionally, ensure you select fasteners that use the correct measurement system. Fasteners are measured in either the metric or imperial systems. In the U.S., the imperial system is standard, while metric sizes are more common internationally. To determine the appropriate standards for your fasteners, consult with industry leaders.

Are you searching for the right fastener standards for your industry or project? Explore resources from the Society of Automotive Engineers (SAE), American Society for Testing and Materials (ASTM), International Organization for Standardization (ISO), and other standards bodies. Confirming compliance with relevant fastener standards ensures quality, compatibility, and regulatory acceptance for your products.

Finding the Right Fastener Supplier

If you are seeking a high-quality fastener, partnering with a reputable industrial fastener supplier or manufacturer is essential. To simplify your search, we have curated a list of top manufacturers on this page, located between our informational sections. Whether you need aerospace fasteners, military-grade fasteners, structural fasteners, electronic fasteners, or jewelry fasteners, you will find suitable options here.

Before exploring the listed manufacturers, ensure you have clearly defined your specifications. We recommend documenting all requirements to avoid overlooking any details. Use this list as a reference when reviewing the manufacturers’ profiles. Select three or four potential candidates and contact each one to discuss your needs, including budget, timeline, and delivery preferences. After these discussions, compare your options and choose the fastener company that best meets your requirements.

Want to accelerate your supplier search? Consider these questions as you evaluate potential fastener manufacturers:

- What certifications and quality systems (such as ISO 9001 or AS9100) does the supplier maintain?

- Can the supplier provide custom fastener design and engineering support for unique applications?

- Does the supplier offer material traceability and documentation for high-spec industries like aerospace and defense?

- What are typical lead times and production capacities for standard and custom orders?

- How does the supplier handle logistics, inventory management, and after-sales support?

Explore our comprehensive fastener manufacturer directory for detailed company profiles, product offerings, and contact information. Streamline your sourcing process and connect with industry leaders delivering reliable, high-performance fastening solutions.

Applications and Benefits of Industrial Fasteners

Industrial fasteners are the backbone of countless assemblies and products, enabling secure, stable, and efficient connections. Their applications cover:

- Automotive Manufacturing: Fasteners enable the assembly of engines, chassis, interiors, and body panels, ensuring safety and performance.

- Aerospace Engineering: Specialized fasteners withstand extreme temperatures, vibrations, and stresses in aircraft, spacecraft, and satellites.

- Construction: Structural fasteners connect beams, columns, and panels, supporting buildings, bridges, and infrastructure projects.

- Electronics: Precision fasteners hold circuit boards, enclosures, and connectors, supporting miniaturization and device reliability.

- Medical Devices: Biocompatible and corrosion-resistant fasteners are used in surgical instruments, implants, and diagnostic equipment.

- Oil & Gas: Fasteners made from high-strength alloys withstand corrosive environments and high pressures in pipelines and refineries.

- Marine Applications: Corrosion-resistant fasteners secure components on ships, docks, and offshore platforms.

- Renewable Energy: Fasteners are critical in wind turbines, solar panels, and hydroelectric systems for secure, durable joins.

- Consumer Goods: Everyday products like furniture, appliances, and sporting equipment rely on fasteners for durability and safety.

Why choose industrial-grade fasteners? Benefits include:

- High Strength: Engineered for demanding loads and harsh environments.

- Durability: Resistant to corrosion, fatigue, and vibration.

- Versatility: Available in a wide range of materials, finishes, and sizes for nearly any application.

- Cost-Efficiency: Reduces maintenance and downtime due to reliable performance.

- Safety: Ensures assemblies meet regulatory and safety standards.

- Customization: Tailored options available for unique projects or challenging conditions.

Frequently Asked Questions about Fasteners

- What is the difference between a bolt and a screw? Bolts typically require a nut for installation and are used to assemble two unthreaded components. Screws often have self-locking capability, with threads designed to engage directly with the material or a prepared hole.

- How do you select the right material for a fastener? Consider environmental exposure, required strength, corrosion resistance, electrical conductivity, and cost. Consult with your fastener supplier for material recommendations based on your application.

- Why are coatings applied to fasteners? Coatings like zinc plating, hot-dip galvanizing, or phosphate improve corrosion resistance, aesthetics, or lubricity, extending fastener life and performance.

- Can fasteners be recycled? Most metal fasteners are recyclable, contributing to sustainability in manufacturing and assembly processes.

- What are tamper-resistant fasteners? These are designed to prevent unauthorized removal or tampering, often used in public infrastructure, electronics, and safety-critical applications.

Ready to source industrial fasteners for your next project or need expert advice? Browse our fastener manufacturer directory or reach out to our team for personalized recommendations and quotations. Whether you need bulk fastener supply, custom solutions, or technical guidance, our network of experienced vendors and engineers can help you achieve reliable, cost-effective results.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services