Our company has a reputation for superior products, customer service, and dependability. All our fastener products are built to last, and we know that our customers appreciate our dedication to using the best materials and manufacturing techniques. If you would like to learn more about us, contact us by phone or email, or stop by our website today!

Self Drilling Screw List

Screws are essential to the automotive, construction, and furniture industries. They hold together everything from drywall to car parts. Where traditional screws require a time-consuming and costly pre-drilled hole for installation, self-drilling screws offer a good alternative.

What are Self-Drilling Screws?

Self-drilling screws are all-in-one fasteners that do not require a pre-drilled hole. Instead, these screws are designed with a sharp point and flute that acts as a drill bit, allowing the screw to drill its hole as it is installed. This feature makes self-drilling screws a time and cost-saving solution, especially for large-scale construction and industrial projects.

Self-drilling screws can be made from various materials, including carbon steel, stainless steel, and titanium. The choice of material depends on the application and environment where the screw will be used. For example, carbon steel self-drilling screws are ideal for general-purpose applications, while stainless steel self-drilling screws are corrosion-resistant and ideal for outdoor use. Titanium self-drilling screws are strong, lightweight, and corrosion-resistant, making them an excellent choice for high-performance applications.

A self-drilling screw has several components: point, flute, shank, threads, and head. The point and flute of a self-drilling screw are designed to drill through materials without needing a pre-drilled hole. The shank is the smooth part of the screw that sits between the threads and the head. The threads grip the material, holding the screw in place. The head of a self-drilling screw can be a flat head, hex head, or pan head.

Benefits & Disadvantages of Self-Drilling Screws

Self-drilling screws offer many benefits, including faster installation, reduced labor costs, and improved productivity. They are also ideal for hard-to-reach areas, such as ceilings or walls, where pre-drilling can be challenging. Self-drilling screws also provide a more secure hold than traditional screws, reducing the risk of screw slippage.

While self-drilling screws offer many advantages, they are not without limitations. For instance, they may not be suitable for some materials, such as hardwood or thick metals, as they may need more power to drill through them. Additionally, self-drilling screws are not designed for high-stress applications or where the joint may be subjected to heavy loads.

Applications of Self-Drilling Screws

Self-drilling screws are used in various industries, as examined in greater detail below:

Construction

Self-drilling screws are commonly used in the construction industry for attaching metal roofing, siding, and drywall. They are ideal for fastening metal framing, such as steel studs and tracks. Unlike traditional screws, self-drilling screws eliminate the need for pre-drilling a hole, saving significant time and effort during installation. Self-drilling screws are also more secure than traditional screws, providing a tighter hold and reducing the risk of screw slippage. Additionally, self-drilling screws are available in various lengths and gauges, making them suitable for a wide range of construction projects.

Automotive

Self-drilling screws are widely used in the automotive industry

for attaching body panels, trim, and other components. They are ideal for drilling through metal and attaching components to a vehicle’s frame. Self-drilling screws are available in different sizes and gauges, allowing for customization based on the specific needs of a project. In addition, self-drilling screws provide a more secure hold than traditional screws, reducing the risk of screws loosening over time.

Metalworking

Self-drilling screws are popular for metalworking applications, such as drilling holes and attaching metal parts. They are particularly useful for drilling into thick metal sheets, as the self-drilling tip eliminates the need for pre-drilling a hole. Self-drilling screws are corrosion-resistant, particularly important for metalworking projects exposed to moisture or harsh weather conditions.

Woodworking

Self-drilling screws are commonly used in woodworking applications, such as attaching wood to metal or wood studs. They are also ideal for fastening wood decking, fencing, and furniture.

Electrical

Self-drilling screws are often used in the electrical industry for securing cable trays, junction boxes, and electrical panels. They are also ideal for installing conduit and other electrical components.

HVAC

In the HVAC industry, self-drilling screws are used for attaching ductwork and other HVAC components. They are also ideal for attaching metal roofing and siding to HVAC units.

Marine

Self-drilling screws are corrosion-resistant, making them an ideal choice for marine applications. They are often used for attaching boat hardware, such as cleats, hinges, and brackets.

Aerospace

Self-drilling screws are used in the aerospace industry for attaching aircraft components, such as panels, brackets, and fasteners. They are also ideal for drilling holes in lightweight materials like aluminum and composites.

Choosing the Correct Self-Drilling Screw Manufacturer

To ensure you have the most positive outcome when purchasing self-drilling screws from a self-drilling screw manufacturer, it is important to compare several companies using our directory of self-drilling screw manufacturers. Each self-drilling screw manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each self-drilling screw business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple self-drilling screw companies with the same form.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

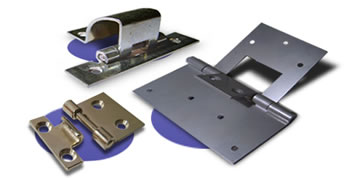

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services