Our company has a reputation for superior products, customer service, and dependability. All our fastener products are built to last, and we know that our customers appreciate our dedication to using the best materials and manufacturing techniques. If you would like to learn more about us, contact us by phone or email, or stop by our website today!

With more than 130,000 commercial and industrial grade fasteners in inventory, our wide distribution network is positioned to get you the parts you need fast. Whether we’re keeping your bins full with a Vendor Managed Inventory Program or rushing emergency replacement parts with 24-hour on-call service, you’ll know that we’ve got you covered. Our HQ’s quality system is certified to AS9120 ...

At DW Fastener, we take pride in our extensive range of fasteners designed to meet the diverse needs of industries worldwide. Industrial fasteners play a crucial role in securely joining various surfaces or objects together in a wide array of applications, and we understand their significance in ensuring the reliability and integrity of your projects.

Blue Ribbon Fastener (BRF) supplies North American OEMs with high-quality fasteners and industrial hardware. Founded in 1985, BRF offers decades of experience and a diverse network of both domestic and international suppliers.

At Warmington Industries, we have built our reputation as a trusted manufacturer and supplier of precision fasteners that support a wide range of industries. We specialize in delivering fastening solutions that meet the exacting demands of construction, manufacturing, automotive, aerospace, and countless other applications where strength, reliability, and consistency are critical.

P&R is a manufacturer of industrial fasteners, specialty fasteners, automotive fasteners, stainless steel fasteners, aerospace and electronic fasteners. We provide over 60 years of experience in designing quality industrial fastener products. Give us a call so we can work together.

Delta Fastener Corp. supplies headed fasteners from only quality manufacturers. Our huge, readily available selection includes industrial bolts, nuts, washers, screws, etc. in a wide range of metal types and grades. Check out our online catalog or give us a call today for industrial bolts and more!

As a fastener manufacturer, Chicago Nut & Bolt wants you to know that your standard fasteners or special fastener in extra-large and extra-long sizes are not a cause for concern. We are used to working with 1/4"-3" diameters and lengths up to 72". Try us for your next needs.

More Plastic Fastener Manufacturers

Plastic fasteners are essential components in a wide range of industries and applications, offering unique advantages over traditional metal fasteners. Available in various plastic materials, colors, fastener head designs, and panel sizes, plastic fasteners are increasingly favored for their versatility, durability, and cost-effectiveness. Whether used in aerospace, automotive, electronics, or consumer products, plastic fasteners help manufacturers meet strict requirements for environmental impact, heat transfer, optical clarity, weight reduction, chemical resistance, and electrical insulation. Their growing popularity stems not only from their functional benefits but also from the broad spectrum of design criteria they satisfy, including strength, flexibility, heat resistance, low-temperature performance, corrosion resistance, sealing ability, and superior dielectric properties. Additionally, the cost of typical plastic fastener materials is often significantly lower than that of their metal counterparts, making them an attractive solution for cost-sensitive projects.

Types of Plastic Fasteners

Choosing the right type of plastic fastener is crucial for ensuring product reliability, safety, and performance. Understanding the differences between non-threaded and threaded plastic fasteners—as well as their various subtypes—helps engineers, designers, and procurement specialists select the ideal component for their specific use case. Below, we explore the primary categories of plastic fasteners and their unique attributes.

Non-Threaded Plastic Fasteners

Non-threaded plastic fasteners, as the name suggests, lack a threaded component. These fasteners are widely used for applications where ease of assembly, vibration resistance, or non-permanent fastening is required. Common examples of non-threaded plastic fasteners include:

- Grommets

- Washers

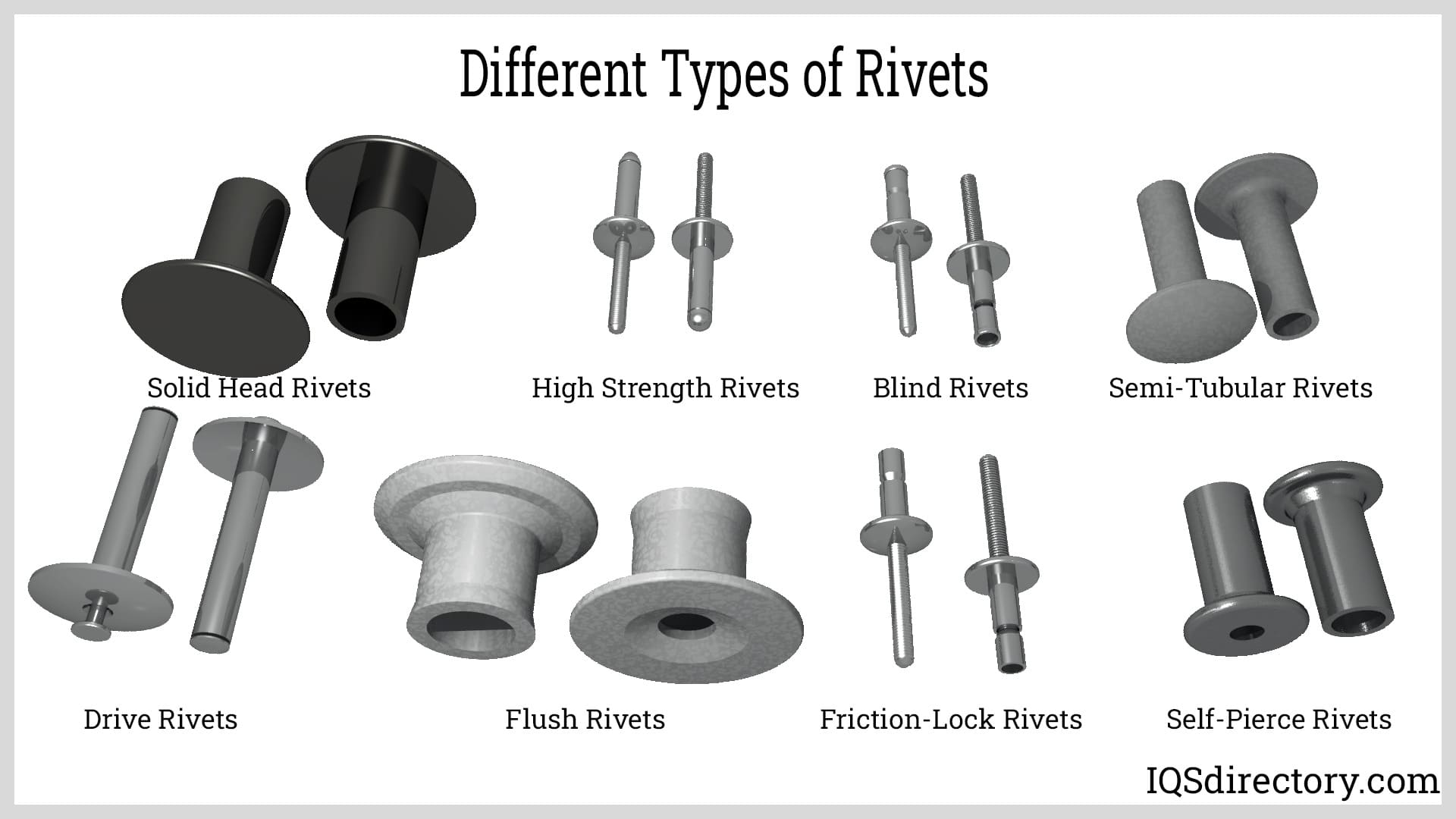

- Rivets

- Pin fasteners

- Retention rings

- Inserts

- Spacers

- Clips

- Harnesses

- Clamps

- Wire bundlers

- Cable ties

Non-threaded fasteners may be generic or may be designed as part of a product family, ensuring compatibility within a specific manufacturer’s ecosystem. These fasteners are often favored for their quick installation, ability to reduce assembly costs, and suitability for applications where frequent removal is necessary. For instance, grommets and spacers provide insulation and protection for wires and cables, while rivets and pin fasteners offer secure, tamper-resistant joining of panels and structural components.

Popular Materials for Non-Threaded Plastic Fasteners

Designers can choose from a variety of engineering plastics for non-threaded fasteners, such as nylon, acetal (POM), polyethylene, polypropylene, polycarbonate, and PVC. Nylon is especially popular for its balance of strength, flexibility, and chemical resistance. Polypropylene offers excellent fatigue resistance and is suitable for living hinges, while polycarbonate provides high impact strength and optical clarity for specialized applications.

Threaded Plastic Fasteners

Threaded plastic fasteners, including plastic screws, nuts, bolts, and threaded studs, feature helical ridges that enable them to grip and hold components securely. These fasteners are ideal for creating strong, reliable assemblies where disassembly may be required. Threaded fasteners are available in a wide range of head styles, drive types, and thread profiles to suit diverse application needs.

Some of the most common materials for threaded plastic fasteners include:

- Nylon (PA6, PA66)

- Polypropylene (PP)

- PVDF (polyvinylidene fluoride)

- Acetal (POM)

- PTFE (polytetrafluoroethylene, also known as Teflon)

These materials are selected for their mechanical strength, chemical resistance, and thermal stability. Threaded plastic fasteners are typically manufactured through injection molding, allowing for precision and consistency in component shape and size. They may be generic or proprietary, depending on the manufacturer and the intended application.

Specialty Threaded Designs

Within the category of threaded plastic fasteners, buyers can find options such as:

- Self-tapping plastic screws—designed to cut their own threads into softer materials, such as plastics and thin metals

- Machine screws—used with pre-tapped holes or paired with plastic nuts

- Thumb screws and wing nuts—for tool-free hand adjustment

- Captive screws—preventing loss during assembly or maintenance

- Shoulder screws—providing precise spacing and alignment

When selecting threaded plastic fasteners, it’s important to consider the mechanical forces involved, the thermal expansion characteristics of the chosen plastic, and the long-term environmental conditions the assembly will encounter.

Key Considerations When Choosing Plastic Fasteners

To maximize the performance and longevity of plastic fasteners, it’s imperative to evaluate several critical factors during the selection process. Here are some of the most important considerations for engineers, product designers, and purchasing managers:

- Thread engagement

- Length of engagement

- Material compatibility

- Mechanical strength requirements

- Environmental exposure (UV, moisture, chemicals, temperature extremes)

- Electrical insulation needs

- Required certifications (UL, RoHS, REACH, etc.)

- Aesthetic requirements (color, finish, transparency)

- Ease of installation and removal

- Cost and availability

Below, we delve deeper into some of these factors, providing guidance on how to evaluate and compare plastic fasteners to ensure optimal fit for your project.

Thread Engagement

The term “thread engagement” refers to the extent to which the threads of a fastener are engaged with the mating material. This is typically expressed as a percentage and is crucial for ensuring the joint’s strength and reliability. For example, in a hole with a diameter equal to the major diameter of the threads, thread engagement would be 0%. In practice, it’s recommended to start with a hole size that provides 75% to 80% thread engagement in moderately stiff materials. Exceeding 100% thread engagement does not improve performance and may increase required drive torque, potentially risking material damage.

Length of Engagement

Length of engagement measures the axial length over which the fastener’s threads are in contact with the mating part (such as a nut or tapped hole). This does not include the lead thread, which is often reduced in diameter and contributes less to holding strength. Properly sizing the length of engagement is important for maximizing load distribution, minimizing the risk of stripping, and ensuring joint integrity, especially in applications subject to vibration or thermal cycling.

Material Compatibility and Environmental Resistance

Choosing the right plastic material for your fastener is crucial. Consider the chemical compatibility with the substrates being joined, as well as the operating environment. For example, fasteners used outdoors or in marine environments should be highly resistant to UV radiation, salt spray, and temperature fluctuations. Nylon and polypropylene offer good resistance to many chemicals, while PVDF and PTFE provide excellent performance in aggressive environments. If you’re unsure which material is best for your application, ask: Which plastic fastener material offers the best combination of strength and chemical resistance for your environment?

Mechanical Strength and Load Requirements

Plastic fasteners are available with a range of mechanical properties, from flexible, impact-resistant designs to rigid, load-bearing options. Evaluate the required tensile, shear, and compressive strengths for your application. For high-load or structural applications, reinforced plastics containing glass or carbon fibers may be appropriate. If your application involves dynamic loads or repeated assembly/disassembly, consider fasteners designed to resist fatigue and creep.

Electrical and Thermal Insulation

One of the greatest benefits of plastic fasteners is their natural electrical insulation properties. This makes them ideal for use in electronics, electrical enclosures, circuit boards, and any application where short-circuit prevention is critical. Additionally, plastics have lower thermal conductivity compared to metals, reducing the risk of heat transfer between connected parts. Explore: Are you seeking fasteners for electronic assemblies that require superior electrical insulation?

Aesthetic and Finishing Needs

Plastic fasteners are available in an extensive range of colors, finishes, and levels of transparency, making them a popular choice for consumer products and applications where appearance matters. Custom coloring or branding is also possible through color-matched plastics or printing. If project aesthetics are important, consider fasteners that blend seamlessly with your product design or branding.

Compliance and Certification

For products sold in regulated markets or industries, it may be necessary to select plastic fasteners that meet specific certifications, such as UL flame ratings, RoHS, or REACH compliance. Always verify certification requirements with your supplier, especially for applications in electrical, medical, or food-contact environments.

Common Uses and Applications of Plastic Fasteners

Plastic fasteners are employed across diverse industries due to their unique combination of properties and cost advantages. Below are some of the most common use cases and application sectors benefiting from plastic fastener technology:

- Aerospace: Lightweight plastic fasteners contribute to reduced aircraft weight, improved fuel efficiency, and easier assembly of cabin interiors, panels, and wire harnesses.

- Electronics and Electrical: Plastic fasteners are essential for printed circuit boards (PCBs), electronic enclosures, cable management, and insulation of sensitive components. Their non-conductive properties prevent short circuits and improve device safety.

- Automotive: Plastic clips, rivets, and screws are widely used in dashboard assemblies, trim panels, engine covers, and under-hood applications due to their resistance to corrosion, vibration, and chemicals.

- Medical Devices: Sterilizable and biocompatible plastics are employed in medical equipment, diagnostic devices, and laboratory instruments where metal fasteners might cause contamination or interfere with imaging.

- Consumer Products: From home appliances to furniture and toys, plastic fasteners provide secure, low-cost joining solutions that can be color-matched or concealed for enhanced aesthetics.

- Industrial Equipment: Plastic fasteners are preferred for chemical processing equipment, HVAC systems, water treatment devices, and clean-room applications where metal corrosion or particle generation is a concern.

- Marine and Outdoor: UV-stabilized and corrosion-resistant plastic fasteners are ideal for use in boats, docks, and outdoor installations exposed to saltwater and sunlight.

Looking for specific application guidance? Ask: What type of plastic fastener works best for your industry or application?

Advantages of Using Plastic Fasteners

In addition to their versatility and application range, plastic fasteners offer compelling benefits that make them the preferred choice for many modern assemblies:

- No rust or corrosion: Unlike metal fasteners, plastic fasteners are immune to rust and corrosion, making them ideal for wet, salty, or chemically aggressive environments. Some plastics, such as PET, Isoplast, and PVC, excel in saltwater exposure thanks to their superior strength-to-weight ratio and resistance to water absorption.

- Cost-effective: The automotive and electronics sectors leverage plastic fasteners for their lower material and production costs compared to metal alternatives. For high-volume projects, the savings can be substantial. If your application requires a large quantity of fasteners, plastics are usually the most economical choice.

- Design flexibility and adaptability: Plastics enable the creation of fasteners in virtually any shape or size, supporting custom designs and innovative assembly solutions. In some cases, a single plastic fastener can replace multiple metal components, reducing complexity and assembly time.

- Low maintenance: Plastic fasteners do not require protective coatings or paints that can chip or wear over time. Their inherent resistance to environmental degradation makes them maintenance-free and reliable for exposed or visible fastener heads.

- Lightweight: The low density of plastics translates into significant weight savings, which is especially valuable in transportation, aerospace, and handheld devices where weight reduction contributes to better performance and fuel efficiency.

- Electrical insulation and safety: Natural dielectric properties make plastic fasteners the go-to choice for electronic and electrical assemblies, preventing dangerous short circuits and improving operational safety.

- Vibration damping: Many engineering plastics provide inherent damping properties, reducing the risk of loosening in assemblies subject to constant movement or vibration.

- Chemical and UV resistance: Select materials offer excellent resistance to acids, bases, solvents, and outdoor weathering, ensuring long-term performance in harsh environments.

- Easy customization: Plastic fasteners can be manufactured to exact specifications, including color matching, branding, and custom geometries for specialized applications.

Still evaluating material choices? Explore: Should you use plastic or metal fasteners for your project requirements?

Factors to Consider When Selecting a Plastic Fastener Supplier or Manufacturer

Choosing a trusted supplier or manufacturer is a critical step in securing high-quality plastic fasteners for your application. Here are some decision factors to guide your search:

- Industry experience and expertise: Look for manufacturers with a proven track record in your industry, whether it’s aerospace, automotive, electronics, or medical devices.

- Material selection and engineering support: Leading suppliers offer extensive material options, technical data sheets, and engineering assistance to help you select the optimal fastener for your needs.

- Custom design and prototyping capabilities: If your project requires non-standard fasteners, prioritize suppliers with in-house design, tooling, and rapid prototyping services.

- Certifications and quality assurance: Ensure your supplier meets necessary standards (ISO, UL, RoHS, REACH) for your target market and application.

- Production capacity and lead times: Evaluate the manufacturer’s ability to support your volume requirements and delivery timelines, especially for large or recurring orders.

- Customer reviews and references: Seek feedback from other buyers and request case studies or references to verify reliability and product performance.

- Supply chain transparency and location: Consider the benefits of domestic versus international suppliers, lead time, and logistics when planning your sourcing strategy.

For the most positive outcome when purchasing plastic fasteners from a plastic fastener manufacturer, it is important to compare several companies using our directory of plastic fastener manufacturers. Each plastic fastener manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or to request a quote. Review each plastic fastener business website using our patented website previewer to quickly learn what each business specializes in. Then, use our simple RFQ form to contact multiple plastic fastener companies with the same form.

Ready to source plastic fasteners? Browse our directory of qualified plastic fastener suppliers and request quotes for your next project.

Frequently Asked Questions (FAQs) About Plastic Fasteners

- What are the main differences between plastic and metal fasteners?

Plastic fasteners are lightweight, corrosion-resistant, non-conductive, and often less expensive than metal fasteners. Metal fasteners typically offer higher mechanical strength and are preferred for heavy structural applications but may corrode or require protective coatings. - Are plastic fasteners strong enough for load-bearing applications?

Many plastic fasteners, especially those made from reinforced engineering plastics, can withstand significant mechanical loads. For structural or critical applications, consult with your supplier to select the appropriate material and design. - Can plastic fasteners be reused?

Some plastic fasteners are designed for repeated assembly and disassembly, while others (such as snap rivets or barbed clips) are intended for single-use. Always check product specifications for reusability. - How can I ensure compatibility between plastic fasteners and the materials being joined?

Verify chemical compatibility, thermal expansion rates, and mechanical requirements before selecting a fastener. Consult with your supplier or review technical data sheets for guidance. - What certifications should I look for when sourcing plastic fasteners?

Depending on your application, you may require certifications such as UL, RoHS, REACH, ISO 9001, or others. Discuss your needs with your chosen manufacturer. - Where can I find custom or specialty plastic fasteners?

Many manufacturers offer custom molding and prototyping services for unique fastener designs. Use our directory to connect with suppliers specializing in custom solutions.

Get Started: Find the Right Plastic Fastener for Your Application

Whether you are designing the next generation of consumer electronics, assembling complex automotive components, or seeking corrosion-resistant alternatives for marine or chemical applications, plastic fasteners offer a compelling blend of performance, cost savings, and design flexibility. By understanding the types, materials, and key selection criteria, you can make informed decisions that improve product reliability and streamline manufacturing.

Ready to take the next step?

- Compare leading plastic fastener manufacturers

- Request technical data sheets or material samples

- Submit a request for quote (RFQ) for custom or standard fasteners

- Discuss your project with application engineers for personalized recommendations

Enhance your designs and assemblies with the unparalleled versatility and value of plastic fasteners—explore your options and source with confidence.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services