Choosing the right fastener can seem overwhelming, but luckily, there are a few considerations that make the decision process easier. Use the following tips to help choose the best specialty fasteners for your product or machines:

Analyze cost: Since fasteners are such an essential part of nearly every product, their importance cannot be overrated. Many companies see fasteners as a low-cost product where they can skimp on cost, but this can end up costing more in the end. Often, using higher quality pieces and well thought-out designs will help a company save money in the end.

Avoid overkill: It is possible to give a fastener manufacturer a too-specific design request for your fasteners. Consider the option of using a different type of fastener in place of a more expensive one if a less expensive fastener can do the job. Maybe a traditional fastener shape can work instead of an unusual, customized design.

Consider end use: Think of how the product will be used before deciding on a fastener type. If the product needs to be opened frequently, metal fasteners are probably a better choice. However, if a product will never be opened, the cheaper alternative of adhesive closures might be a better option.

Explore new technology: Don’t limit yourself to traditional fastener types. Many manufacturers are constantly creating new ways to fasten products, and some of the new methods might be perfect for your product.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

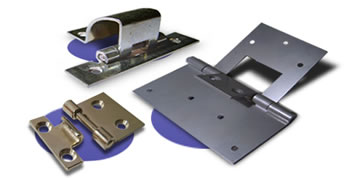

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

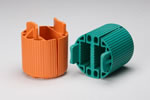

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services