Our company has a reputation for superior products, customer service, and dependability. All our fastener products are built to last, and we know that our customers appreciate our dedication to using the best materials and manufacturing techniques. If you would like to learn more about us, contact us by phone or email, or stop by our website today!

With more than 130,000 commercial and industrial grade fasteners in inventory, our wide distribution network is positioned to get you the parts you need fast. Whether we’re keeping your bins full with a Vendor Managed Inventory Program or rushing emergency replacement parts with 24-hour on-call service, you’ll know that we’ve got you covered. Our HQ’s quality system is certified to AS9120 ...

At DW Fastener, we take pride in our extensive range of fasteners designed to meet the diverse needs of industries worldwide. Industrial fasteners play a crucial role in securely joining various surfaces or objects together in a wide array of applications, and we understand their significance in ensuring the reliability and integrity of your projects.

Blue Ribbon Fastener (BRF) supplies North American OEMs with high-quality fasteners and industrial hardware. Founded in 1985, BRF offers decades of experience and a diverse network of both domestic and international suppliers.

At Warmington Industries, we have built our reputation as a trusted manufacturer and supplier of precision fasteners that support a wide range of industries. We specialize in delivering fastening solutions that meet the exacting demands of construction, manufacturing, automotive, aerospace, and countless other applications where strength, reliability, and consistency are critical.

P&R is a manufacturer of industrial fasteners, specialty fasteners, automotive fasteners, stainless steel fasteners, aerospace and electronic fasteners. We provide over 60 years of experience in designing quality industrial fastener products. Give us a call so we can work together.

Delta Fastener Corp. supplies headed fasteners from only quality manufacturers. Our huge, readily available selection includes industrial bolts, nuts, washers, screws, etc. in a wide range of metal types and grades. Check out our online catalog or give us a call today for industrial bolts and more!

As a fastener manufacturer, Chicago Nut & Bolt wants you to know that your standard fasteners or special fastener in extra-large and extra-long sizes are not a cause for concern. We are used to working with 1/4"-3" diameters and lengths up to 72". Try us for your next needs.

More Stainless Steel Screw Manufacturers

Stainless steel screws are widely used fasteners known for their exceptional performance and durability. These screws are primarily utilized in construction, infrastructure, marine, automotive, electronics, machinery, heavy equipment, furniture assembly, and various other industries.

Benefits of Stainless Steel Screws

Stainless steel screws offer numerous advantages over other materials. To start, their corrosion resistance ensures long-lasting performance, even in challenging environments exposed to moisture or chemicals. The inherent strength and durability of stainless steel also make it suitable for applications requiring high load-bearing capacity. Additionally, stainless steel screws enhance the aesthetic appeal of finished products and provide a sleek and polished finish. Furthermore, their ability to withstand extreme temperatures makes them ideal for applications exposed to heat or cold.

Varieties of Stainless Steel Screw Designs

Stainless steel screws are available in various designs to cater to specific application requirements. Phillips head screws, commonly used in general construction, provide excellent torque transfer and are easily installed and removed. Hex head screws, meanwhile, find extensive use in the automotive industry due to their compatibility with wrenches and high torque resistance. Additionally, Torx™ screws, featuring a star-shaped recess, are commonly used in electronics and appliances, providing increased resistance to stripping. Furthermore, socket head screws, with a cylindrical recess, are preferred for machinery and heavy equipment, as they provide higher torque capacity and improved structural integrity. Finally, flat head screws are commonly used in furniture assembly, offering a flush and neat appearance.

Additional Varieties of Stainless Steel Screws

In addition to design variations, stainless steel screws also come in various other variations to cater to specific application needs. To start, self-drilling stainless steel screws feature drill-like points and eliminate the need for pre-drilling, making them ideal for efficient installations in metal framing or roofing. Self-tapping stainless steel screws, meanwhile, have threads designed to tap into materials, creating their own threads and providing secure connections in metal-to-metal or plastic-to-metal applications. Thread-cutting stainless steel screws, on the other hand, are designed to cut threads into low shear strength materials like wood or plastics. Additionally, stainless steel machine screws are used with nuts to fasten parts together, while stainless steel lag screws offer heavy-duty strength for load-bearing applications. Finally, stainless steel set screws secure objects or components within or against another object. Stainless steel set screws are commonly used in automotive applications to secure various components such as electrical connectors, sensors, or small brackets, ensuring a secure and reliable fastening solution in demanding environments.

Considerations Regarding Stainless Steel Screws

While stainless steel screws offer many benefits, there are certain considerations to keep in mind. Cost is often a factor, as stainless steel screws tend to be more expensive than their counterparts made from other materials. Additionally, stainless steel can experience increased hardness, known as work-hardening, when used with mechanical work, making it more challenging to drill or modify the screws. Under specific conditions, such as exposure to extreme temperatures or certain chemicals, stainless steel screws can also become brittle and prone to breakage.

Manufacturers Address These Considerations

To overcome these considerations, manufacturers of stainless steel screws have made significant efforts. They have developed cost-effective stainless steel alloys that maintain high performance while offering more affordable options. Surface treatments, such as coatings or platings, are now applied to stainless steel screws to improve their performance, enhance corrosion resistance, and reduce friction during installation. Furthermore, ongoing research and development aim to create stainless steel alloys with improved strength, flexibility, and resistance to brittleness under challenging conditions.

Applications of Stainless Steel Screws

The versatility of stainless steel screws allows them to be employed in a wide range of applications. In the construction and infrastructure sector, for instance, stainless steel screws secure structural components, such as beams and panels. In marine and coastal environments, meanwhile, they resist corrosion caused by saltwater exposure. Likewise, the food processing and pharmaceutical industries utilize stainless steel screws with the equipment used to manufacture their products due to their hygienic properties. Stainless steel screws are also integral to renewable energy projects, providing secure fastening for solar panels, wind turbines, and geothermal systems. Additionally, stainless steel screws find extensive use in the automotive industry, electronics, appliances, machinery, heavy equipment, and furniture assembly.

The Future Outlook for Stainless Steel Screws

The future of stainless steel screws holds promising advancements. Ongoing developments in material science and engineering aim to create innovative stainless steel alloys with enhanced properties, such as increased strength-to-weight ratio and improved resistance to extreme conditions. Integration with smart technologies, such as embedded sensors or corrosion monitoring systems, could enable real-time performance tracking and maintenance. Moreover, sustainable manufacturing practices and recycling initiatives may contribute to reducing the environmental impact associated with stainless steel screw production and disposal.

Choosing the Correct Stainless Steel Screw Supplier

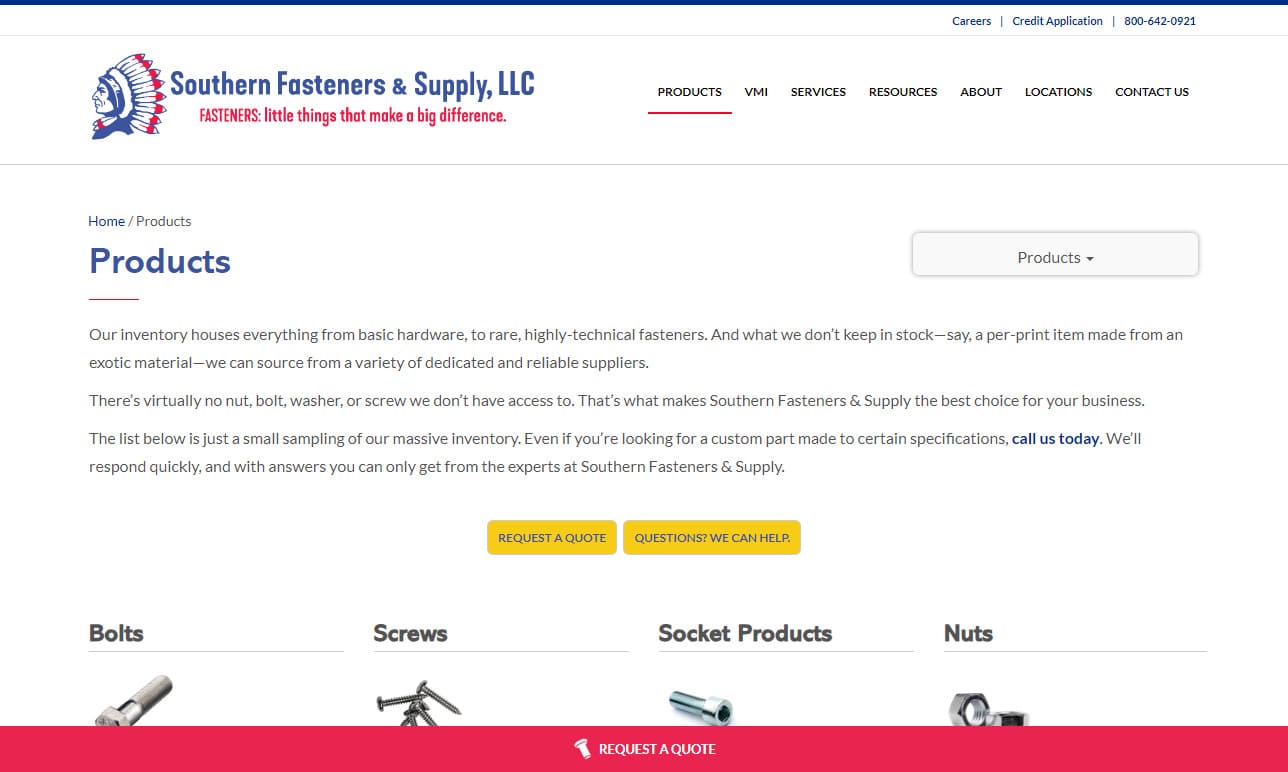

To ensure you have the most positive outcome when purchasing stainless steel screws from a stainless steel screw supplier, it is important to compare several companies using our directory of stainless steel screw suppliers. Each stainless steel screw supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each stainless steel screw business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple stainless steel screw companies with the same form.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services